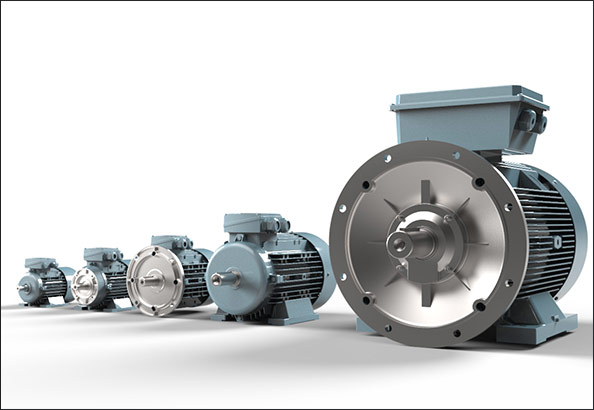

Three Phase Motor

Product Details

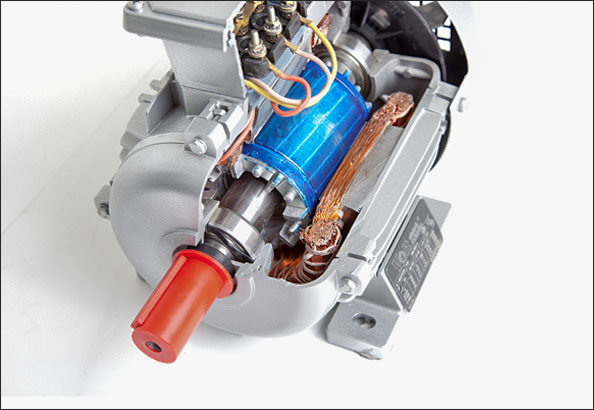

Rotor is the rotating part of the motor. There is wind in the rotors of the slip-ring asynchronous motors, and short-circuited bars in the rotor of the squirrel-cage asynchronous motors. The asynchronous motor type generally used in industrial implementations is the squirrel-cage asynchronous motor. The industrial asynchronous motor product range of Volt Motor consists of squirrel-cage asynchronous motors.

n asynchronous motors, the frequency of the rotating field created in the air gap and the rotation frequency of the rotor are not the same. These motors are called asynchronous for this reason. The frequency of the rotating field in the air gap depends on the motor’s feed frequency and the number of poles and does not change with the motor’s load, but the rotation frequency of the rotor varies according to the load. As the load increases in the motor operation area, the motor rotation speed decreases, and the motor rotation speed increases as the load decreases. The motor rotation speed is the highest in idle mode. The motor rotation speed of the asynchronous motor in the motor operation area cannot exceed the rotation speed of the rotating field. The rotation speed of the rotating field is calculated as follows:

N = 120 * F / P

- N: rotation speed of rotating field [rpm]

- f: feed frequency [Hz]

- P: number of poles of stator winding

As is seen here, the rotating field speed of a 2-pole motor will be 3000rpm and the rotating field speed of a 4-pole motor will be 1500rpm. The change in the rotation speed of the asynchronous motor at different loads can be seen in the torque-speed graph shown below. 3-phase asynchronous motors; can be used directly by operating from the network (DOL). In this case, speed adjustment is not possible. can be used by feeding with a variable speed driver (VFD) for speed control and are suitable for both scaler and vectorial control. The same motor can be used in both 50Hz and 60Hz networks. are suitable for Star/Triangle start-up or soft starter usage for limitation of start-up current.

Related Product

Dynamic Blower

Roots blowers operate by trapping a fixed amount of fluid or gas and expelling it against the system's pressure.

Read more

Dynamic Vessel

FRP is an updated composite material used for chemical plant appliances and equipment, including vessels and tanks.

Read more

Dynamic Flow Meter

Dynamic Flow Computers is one of the main global providers of advanced flow measurement solutions.

Read more

Dynamic Motor

Dynamic Motors strives to find you the best deals in the pre-owned vehicle market. As a company, we have years of experience and expertise.

Read more

Dynamic RO Membrane

There are many applications for RO, including water and wastewater treatment, food and beverage processing, and pharmaceutical production.

Read more

Dynamic Pump

Dynamic pumps use kinetic energy to move liquids, like water and oil, from a lower to a higher pressure.